How Distributed Acoustic Sensing Systems Benefit Oil and Gas Companies

It’s now over 20 years since the first fiber optics sensing system was invented and successfully utilized in the oilfield. The simple temperature and point pressure sensor first used in 1993 in some Netherlands land well have given room for the creation of better and more advanced systems. It has also seen people permanently move into the use of in-well monitoring systems. The use of distributed acoustic sensing (DAS) systems has seen the introduction of well-known and credible manufacturers like https://fibrecompletions.com/distributed-acoustic-sensing-das/. More oil and gas companies are investing in these smart and internet of things systems as they fully well know the benefits they can reap from using them.

Timely Provision of Information

High-end permanent in-well fiber optics sensing installations deliver timely and quality information all through the period of well drilling. The real-time provision of viable data and information makes it easier for oil and gas company operators to optimize completion design, placement of the wells, and spacing. The firsthand information they get helps them to easily identify curve depletion to take the right actions and moves on time.

Reliable and Efficient

Distributed acoustic sensing systems from trusted manufacturers are inherently reliable. Known for providing high-quality and efficient downhole sensing systems that are intrinsically safe, resistant to EM radiation and has non-moving parts, https://fibrecompletions.com/about-us/, will make sure your oil and gas well is completed on time and at lower costs. That’s true since the systems are intended to improve reliability, lower cases of cost of ownership, and decrease cases of downtimes.

Offers Full Coverage

The best in the market acoustic sensing systems will cover all the drilling paces throughout the wellbore process. The systems will always send real-time information regarding the integrity of different components and systems. This simply means enhanced condition monitoring and less unexpected downtimes with advanced optimization of asset maintenance.

Continuous Information Distribution

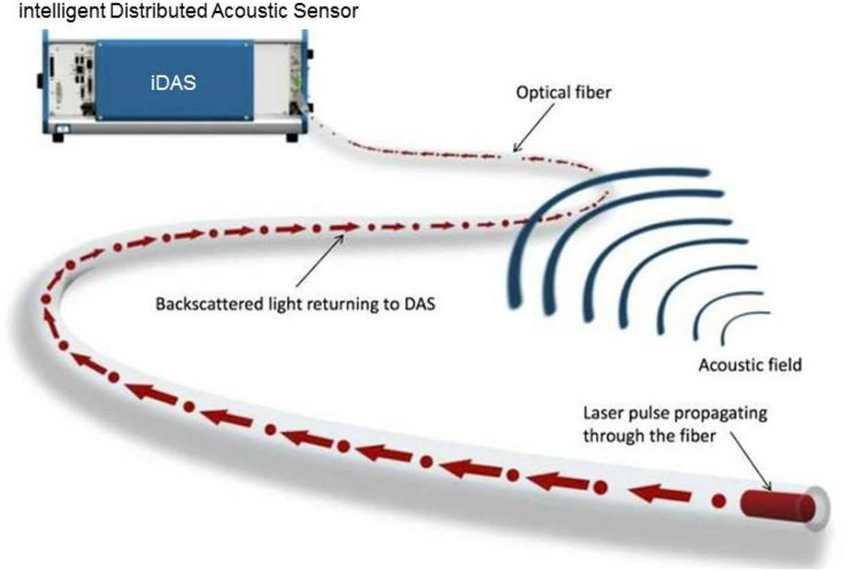

Distributed acoustic sensing systems work in rhythm to distribute real-time information throughout the fracturing operations. The instantaneous optimization of different wellbore processes and operations will help decrease the cost of operation. That is possible as real-time operation optimization aids to advance production and lower material costs. Minimal wastage and maximum production will always guarantee lower operation cost and boosted operations.

Conclusion

Oil and gas companies can never be sure of their success if they haven’t invested in the right fiber optics and acoustic sensing systems. Since they cannot monitor the flow and performance of their wells, it’s always very possible to make mistakes that can go a long way in increasing their operation costs and drilling time. There are many manufacturers and manufacturers of fiber optic sensing systems around the world but only a few can be trusted.